How to setting Relay Coordination

1. Standard and Code

- NEC Article 430-32 (Continuos - Duty Motors)

- NEC Article 430-126 (Rating of Motor Control Apparatus)

- IEEE Std 141-1976, IEEE Recommended Practice for Electrical Power Distribution for Industrial Plants

- IEEE Std 242-1986, IEEE Recommended Practice for Protection and Coordination of Industrial and Commercial Power System

- IEEE C37.101-1993, IEEE Guide for AC Generator Ground Protection

- IEEE C37.102-1987, IEEE Guide for AC Generator Protection

2. Principles of Protective Relay Application

Fault protection relaying can be classified into two groups, primary relaying which should function first in removing faulted equipment from the system, and backup relaying which functions only when primary relaying fails. For complete explanation, see IEEE Std 141-1976 (IEEE Recommended Practice for Electric Power Distribution for Industrial Plants).

3. Methodology / Calculation Criteria

The study is based on the data

and parameter as defined below:

- The study is performed by Power Plot version 2.5. The Power Plot v.2.5 has provided some fixtures which used as parameter in this project as follow:

- Transformer thermal damage and inrush currentcurve

- Cable thermal damage curve

- Motor Starting Curve

- MCP & MCCB curve

- User curve

- Available 3 phase short circuit current at all relevant buses

3.1 Generator Protection

3.1.1 Generator

Data

Gas Turbine

Generator

”A/B”

|

Diesel Engine

Generator

|

|

Engine Manufacturer

|

||

Generator manufacturer

|

||

kW rating

|

1100

|

650

|

kV rating

|

0.4

|

0.4

|

PF rating

|

0.8

|

0.8

|

Frequency Rating

|

50

|

50

|

FLA Rating (A)

|

1985

|

1173

|

Reactance (unsat)

|

||

Synchronous, Xd (%)

|

103.6

|

303.42

|

Transient, X’d (%)

|

13.8

|

22.1

|

Subtransient, X”d (%)

|

11

|

15.51

|

Motoring Power (kW)

|

120

|

|

Unbalanced Capability

|

see attachment #2

|

see attachment #2

|

Generator protection is using

GE - Multilin SR 489. The 489 Generator Management Relay is a

microprocessor-based relay designed for the protection and management of

synchronous and induction generator.

Refer to below paragraph for

the SR489 relay setting.

3.1.3 Setpoint /

System Setup

Current

Sensing

Gas Turbine

Generator

”A/B”

|

Diesel Engine

Generator

|

|

Phase Current

|

||

Primary CT

|

2500 Amps

|

1200 Amps

|

Ground Current

|

||

Ground CT Type

|

5 A Secondary

|

5 A Secondary

|

Ground CT Ratio

|

50/5

|

50/5

|

Voltage

Sensing

Gas Turbine

Generator

”A/B”

|

Diesel Engine

Generator

|

|

Voltage Transformer

|

||

VT Connection Type

|

Open Delta

|

Open Delta

|

Transformer Ratio

|

33.3

|

33.3

|

Generator

Parameters

Gas Turbine

Generator

”A/B”

|

Diesel Engine

Generator

|

|

Generator

Rated MVA

|

1.375 MVA

|

0.812 MVA

|

Generator

Rated Power Factor

|

0.8

|

0.8

|

Generator

Voltage Phase-Phase

|

400 V

|

400 V

|

Generator

Nominal Frequency

|

50 Hz

|

50 Hz

|

Generator

Phase Sequence

|

ABC

|

ABC

|

Serial

Start/Stop Initiation

None

3.1.4 Setpoint /

Digital Input

Breaker

Status

Gas Turbine

Generator

”A/B”

|

Diesel Engine

Generator

|

|

Breaker

Status

|

Breaker Auxiliary A

|

Breaker Auxiliary A

|

General

Purpose

None

Predefined

None

Generator

Switch Status

None

3.1.5 Setpoint / Output Relay

Gas Turbine

Generator

”A/B”

|

Diesel Engine

Generator

|

|

Relay Reset Mode

|

||

R1

Trip

|

All Resets

|

All Resets

|

R2

Auxiliary

|

All Resets

|

All Resets

|

R3

Auxiliary

|

All Resets

|

All Resets

|

R4

Auxiliary

|

All Resets

|

All Resets

|

R5

Alarm

|

All Resets

|

All Resets

|

R6

Service

|

All Resets

|

All Resets

|

3.1.6 Setpoint /

Protection

3.1.6.1 Current

Element

Overcurrent Alarm

·

Consideration/formula

This feature is intended to

give the time for operator to analyze and asses the situation when

overload of generator occurred.

·

Setting

GPR for GTG

”A/B”

|

GPR for DEG

|

|

Overcurent

Alarm

|

Unlatched

|

Unlatched

|

Assign

Alarm Relay (2-5)

|

5

|

5

|

Overcurent

Alarm Level

|

1.01 x

|

1.1 x

|

Overcurent

Alarm Delay

|

3 s

|

3 s

|

Overcurent

Alarm Event

|

On

|

On

|

Offline O/C

·

Consideration/formula

This feature is active only

when generator is OFFLINE and uses the neutral measurements end CT. It is set

more sensitive than differential relay to detect high impedance phase faults.

Since the breaker auxiliary

contacts wired to the 489 Breaker Status Input may not operate at exactly the

same time as the main breaker contact, the time delay should be coordinate with

the difference of the operation times.

·

Setting

GPR for GTG

”A/B”

|

GPR for DEG

|

|

Offline

Overcurrent Trip

|

Unlatched

|

Unlatched

|

Assign

Trip Relay (1-4)

|

1, 3

|

1, 3

|

Offline

Overcurrent Pickup

|

0.05 x CT

|

0.8 x CT

|

Offline

Overcurrent Delay

|

10 Cycles

|

10 Cycles

|

Inadvertent Energize

·

Consideration/formula

This relay is intended to

protect a poor synchronizing by “U/V or Offline”.

·

Setting

GPR for GTG

”A/B”

|

GPR for DEG

|

|

Inadvertent

Energize Trip

|

Unlatched

|

Unlatched

|

Assign

Trip Relay (1-4)

|

1, 3

|

1, 3

|

Arming

Signal

|

UV and Offline

|

UV and Offline

|

Inadvertent

Energize O/C Pickup

|

0.15 x CT

|

0.15 x CT

|

Inadvertent

Energize Pickup

|

0.95 x

Rated Volt

|

0.95 x

Rated Volt

|

Phase Overcurrent

·

Consideration/formula

This relay is as backup

protection and shall be coordinated with downstream “relay” to avoid

overlapping protection. (see relay coordination case #5 & #6 on the

paragraph 4.7 & 4.8 )

·

Setting

GPR for GTG

”A/B”

|

GPR for DEG

|

|

Phase

Overcurrent Trip

|

Latched

|

Latched

|

Assign

Trip Relay (1-4)

|

1, 3

|

1, 3

|

Enable

Voltage Restraint

|

No

|

No

|

Phase

Overcurrent Pickup

|

2 x CT

|

1.4 x CT

|

Curve

Shape

|

Definite Time

|

Definite Time

|

Overcurrent

Curve Multiplier

|

2

|

2

|

Overcurrent

Curve Reset

|

Instantaneous

|

Instantaneous

|

Negative Sequence

·

Consideration/formula

The relay should be set to

lower than I22t limit of the generator being protected.

The actual generator unbalance current capability shall be plotted in the

common scale (Log-Log) and then the relay (constant K) can be adjusted to get optimum setting of this relay

·

Setting

GPR for GTG

”A/B”

|

GPR for DEG

|

|

Negative Sequence Alarm

|

Latched

|

Latched

|

Assign Alarm Relay (2-5)

|

5

|

5

|

Neg. Sequence Alarm

Pick-up

|

5%

|

5%

|

Negative Sequence

Alarm Delay

|

5 s

|

5 s

|

Negative Sequence

Alarm Event

|

On

|

On

|

Negative Sequence O/C

Trip

|

Latched

|

Latched

|

Assign Trip Relay

(1-4)

|

1, 3

|

1, 3

|

Neg. Sequence Trip

Pick-up

|

20%

|

20%

|

Neg. Sequence O/C

Constant K

|

5

|

5

|

Neg. Sequence O/C

Max. Time

|

125 s

|

125 s

|

Neg. Sequence O/C

Reset Rate

|

150 s

|

150 s

|

Ground O/C

The ground O/C protection is

not used since generator is grounded through a ground fault neutralizer (HRG

device) to operate alarm and to give the time for operator to analyze and asses

the situation and tripping will be delayed as long as an hour or two to permit

fault insulation.

Phase Differential

·

Consideration/formula

·

Setting

GPR for GTG

”A/B”

|

GPR for DEG

|

|

Phase

Differential Trip

|

Unlatched

|

Unlatched

|

Assign

Trip (1-4)

|

1, 2, 3

|

1, 2, 3

|

Differential

Trip Min Pick-up

|

0.1 x CT

|

0.1 x CT

|

Differential

Trip Slope 1

|

10%

|

10%

|

Differential

Trip Slope 2

|

20%

|

20%

|

Differential

Trip Delay

|

10 cycles

|

10 cycles

|

Ground Directional

Not applicable since the 59N

is not used in this project.

High-set Phase O/C

·

Consideration/formula

This element

can be used as back-up feature to overcurrent. It is set above the maximum current

contribution from generator when parallel operation.

The maximum

current contribution from GTG and DEG to the fault are 18.7kA &

10.8kA.

·

Setting

GPR for GTG

”A/B”

|

GPR for DEG

|

|

High-Set

Phase O/C Trip

|

Unlatched

|

Unlatched

|

Assign

Trip (1-4)

|

1, 3

|

1, 3

|

High-Set

Phase O/C Pickup

|

2.2 x CT

|

1.6 x CT

|

High-Set

Phase O/C Delay

|

0.6s

|

0.6s

|

3.1.6.2 Voltage

Element

Undervoltage

·

Consideration/formula

Refer to General Electrical

Design Specification PS-1100-ELE-001 voltage drop on the bus max. drop 6% at steady state condition and 15% at transient

condition.

·

Setting

GPR for GTG

1147-GTG-600”A/B”

|

GPR for DEG

1147-DEG-620

|

|

Undervoltage

Alarm

|

Unlatched

|

Unlatched

|

Assign

Alarm Relays (2-5)

|

5

|

5

|

Undervoltage

Alarm Pickup

|

0.87 x Rated

|

0.87 x Rated

|

Undervoltage

Alarm Delay

|

2.3 s

|

2.3 s

|

Undervoltage

Trip

|

Latched

|

Latched

|

Assign

Trip Relays (1-4)

|

1,3

|

1,3

|

Undervoltage

Trip Pickup

|

0.85 x Rated

|

0.85 x Rated

|

Undervoltage

Trip Delay

|

2 s

|

2 s

|

Undervoltage

Curve Reset Rate

|

3 s

|

3 s

|

Undervoltage

Curve Element

|

Curve

|

Curve

|

Overvoltage

·

Consideration/formula

Generator overvoltage may

occur without necessarily exceeding the volts/Hz limits of the machine. In

general, this not problem with steam and gas turbine generators because of the

rapid response of the speed-control system and voltage regulator.

The instantaneous unit is

generally set to pickup at about 130% - 150% of nominal voltage (see IEE

C17.102-1987).

·

Setting

GPR for GTG

1147-GTG-600”A/B”

|

GPR for DEG

1147-DEG-620

|

|

Overvoltage

Alarm

|

Unlatched

|

Unlatched

|

Assign

Alarm Relays (2-5)

|

5

|

5

|

Overvoltage

Alarm Pickup

|

1.05 x rated

|

1.05 x rated

|

Overvoltage

Alarm Delay

|

2 s

|

2 s

|

Overvoltage

Trip

|

Latched

|

Latched

|

Assign

Trip Relays (1-4)

|

1,3

|

1,3

|

Overvoltage

Trip Pickup

|

1.1 x rated

|

1.1 x rated

|

Overvoltage

Trip Delay

|

1 s

|

1 s

|

Overvoltage

Curve Reset Rate

|

3 s

|

3 s

|

Overvoltage

Curve Element

|

Curve

|

Curve

|

Volt / Hertz

Not applicable since it is used for protection integral generator and

transformer

Phase Reversal

·

Consideration/formula

This feature is intended to

protect phase rotation.

·

Setting

GPR for GTG

1147-GTG-600”A/B”

|

GPR for DEG

1147-DEG-620

|

|

Phase

Reversal Trip

|

Latched

|

Latched

|

Assign

Trip Relays (1-4)

|

1, 3

|

1, 3

|

Underfrequency

Not applicable since using individual Relay 81 for underfrequency detection

Overfrequency

None

Neutral O/V (Fund.)

Not applicable since no detection device

Neutral U/V (3rd)

Not applicable since no detection device

Loss of Excitation

·

Consideration/formula

A. Loss

of excitation setting for Gas Turbine Generator (GTG)

= 16.02 W

X’d (sec) = Zbase x X’dpu

= 16.02

x 0.138 = 2.21 secondary ohms

Xd (sec) = Zbase x Xdpu

= 16.02

x 1.036 = 16.59 secondary ohms

\

Diameter =  = 16.59 W

= 16.59 W

B. Loss of excitation

setting for Diesel Engine Generator (DEG)

·

Setting

GPR for GTG

1147-GTG-600”A/B”

|

GPR for DEG

1147-DEG-620

|

|

Enable

Voltage Supervision

|

Yes

|

Yes

|

Voltage

Level

|

0.70 x Rated

|

0.70 x Rated

|

Circle

1 Trip

|

Latched

|

Latched

|

Assign

Circle 1 Trip Relays (1-4)

|

1, 2, 3

|

1, 2, 3

|

Circle

1 Diameter

|

15.5 Wsec

|

29 Wsec

|

Circle

1 Offset

|

3.7 Wsec

|

7 Wsec

|

Circle

1 Trip Delay

|

3s

|

3s

|

Circle

2 Trip

|

Latched

|

Latched

|

Assign

Circle 2 Trip Relays (1-4)

|

1, 2, 3

|

1, 2, 3

|

Circle

2 Diameter

|

22.2 Wsec

|

42 Wsec

|

Circle

2 Offset

|

3.7 Wsec

|

7 Wsec

|

Circle

2 Trip Delay

|

4 s

|

4 s

|

Distance

Not applicable since it is intended for transmission line

3.1.6.3 Power

Element

Reactive Power

Not necessary

Low Forward Power

Not necessary

Reverse Power Trip

·

Consideration/formula

According to ANSI Std

C37-102-1987, the gas turbine prime mover usually have capability maximum

motoring power up to 50% of rating and a diesel engine with no cylinder firing

represented a load of up to 25% of rating, so the sensitivity is not critical.

In this project, there are

two types of generator, gas turbine generator and diesel engine generator. The

sensitivity of reverse power relay is not critical problem due to large power

required to motor.

·

Setting

GPR for GTG

1147-GTG-600”A/B”

|

GPR for DEG

1147-DEG-620

|

|

Block Reverse Power From

Online

|

2 s

|

2 s

|

Reverse

Power Alarm

|

Unlatched

|

Unlatched

|

Assign

Alarm Relays (2-5)

|

5

|

5

|

Reverse

Power Alarm Level

|

0.04 x Rated MW

|

0.04 x Rated MW

|

Reverse

Power Alarm Delay

|

25 s

|

20 s

|

Reverse

Power Trip

|

Latched

|

Latched

|

Assign

Trip Relays (1-4)

|

1,3

|

1,3

|

Reverse

Power Trip Level

|

0.06 x Rated MW

|

0.06 x Rated MW

|

Reverse

Power Trip Delay

|

5 s

|

12 s

|

3.1.6.4 RTD

Element

Disable

3.1.6.5 Thermal

Mode.

Disable

3.1.7 Setpoint /

Monitoring

Trip Counter

·

Setting for All Generators

GPR for GTG

1147-GTG-600”A/B”

|

GPR for DEG

1147-DEG-620

|

|

Trip Counter Alarm

|

Latched

|

Latched

|

Assign

Alarm Relay (2-5)

|

5

|

5

|

Trip

Counter Alarm Level

|

10 trips

|

10 trips

|

Trip

Counter Alarm Event

|

ON

|

ON

|

Breaker Failure

·

Setting for All Generators

GPR for GTG

1147-GTG-600”A/B”

|

GPR for DEG

1147-DEG-620

|

|

Breaker Failure Alarm

|

Unlatched

|

Unlatched

|

Assign

Alarm Relay (2-5)

|

5

|

5

|

Breaker

Failure Level

|

1.1 x CT

|

1.1 x CT

|

Breaker

Failure Delay

|

80 ms

|

80 ms

|

Breaker

Failure Alarm Event

|

ON

|

ON

|

Trip Coil Monitor

·

Setting for All Generators

GPR for GTG

1147-GTG-600”A/B”

|

GPR for DEG

1147-DEG-620

|

|

Trip Coil Monitor Alarm

|

Unlatched

|

Unlatched

|

Assign

Alarm Relay (2-5)

|

5

|

5

|

Supervision

of Trip coil

|

52 Closed

|

52 Closed

|

Trip

Coil Monitor Alarm Event

|

ON

|

ON

|

VT Fuse Failure

·

Setting for All Generators

GPR for GTG

1147-GTG-600”A/B”

|

GPR for DEG

1147-DEG-620

|

|

VT Fuse Alarm

|

Unlatched

|

Unlatched

|

Assign

Alarm Relay (2-5)

|

5

|

5

|

VT

Fuse Alarm Event

|

ON

|

ON

|

Current Demand

·

Setting for All Generators

GPR for GTG

1147-GTG-600”A/B”

|

GPR for DEG

1147-DEG-620

|

|

Current Demand Period

|

15 min

|

15 min

|

Current

Demand Alarm

|

Unlatched

|

Unlatched

|

Assign

Alarm Relay (2-5)

|

5

|

5

|

Current

Demand Limit

|

1.01 x

|

1.01 x

|

Current

Demand Alarm Event

|

ON

|

ON

|

MW Demand

·

Setting for All Generators

GPR for GTG

1147-GTG-600”A/B”

|

GPR for DEG

1147-DEG-620

|

|

MW Demand Period

|

15 min

|

15 min

|

MW

Demand Alarm

|

Unlatched

|

Unlatched

|

Assign

Alarm Relay (2-5)

|

5

|

5

|

MW

Demand Limit

|

1.01 x Rated

|

1.01 x Rated

|

MW

Demand Alarm Event

|

ON

|

ON

|

MVAR Demand

·

Setting for All Generators

GPR for GTG

1147-GTG-600”A/B”

|

GPR for DEG

1147-DEG-620

|

|

MVAR Demand Period

|

15 min

|

15 min

|

MVAR

Demand Alarm

|

Unlatched

|

Unlatched

|

Assign

Alarm Relay (2-5)

|

5

|

5

|

MVAR

Demand Limit

|

1.11 x Rated

|

1.11 x Rated

|

MVAR

Demand Alarm Event

|

ON

|

ON

|

MVA Demand

·

Setting for All Generators

GPR for GTG

1147-GTG-600”A/B”

|

GPR for DEG

1147-DEG-620

|

|

MVA Demand Period

|

15 min

|

15 min

|

MVA

Demand Alarm

|

Unlatched

|

Unlatched

|

Assign

Alarm Relay (2-5)

|

5

|

5

|

MVA

Demand Limit

|

1.1 x Rated

|

1.1 x Rated

|

MVA

Demand Alarm Event

|

ON

|

ON

|

Pulse Output

Disable

Generator Running Hour Setup

·

Setting for All Generators

GPR for GTG

1147-GTG-600”A/B”

|

GPR for DEG

1147-DEG-620

|

|

Initial Gen. Running Hours

|

0 h

|

0 h

|

Gen.

Running Hours Alarm

|

Unlatched

|

Unlatched

|

Assign

Alarm Relay (2-5)

|

5

|

5

|

Gen.

Running Hour Limit

|

1000 h

|

1000 h

|

3.2 Motor Protection

3.2.1 Largest motor at MCC “A & B”

§

Protective Scheme One Line Diagram

§

Protected Equipment:

The

protection is intended to protect motor against overload, short-circuit and

locked rotor.

·

Tag Number :

1130-KM-310A/B – Propane Compressor

·

Model, Manufacturer : Squirrel cage induction motor / Toshiba

·

Rating :

300 HP

·

Full load CURRENT (FLA) : 378.1Amps

·

Locked Rotor :

6 x FLA

·

Starting Device :

Soft Starter (manufacturer: ABB)

·

Service factor :

1.15

§

Protective device:

·

The Overload (OL) device

o

Model, Manufacturer : CEFB1-52-120VAC, Allen Bradley

o

Rating Trip Range : 160 – 630A

·

The motor circuit protection (MCP)

o Manufacturer : Merlin Gerin

o Model : NS630H, MA500 # 32950

o Type : MCCB 3P

o Frame : 500 Amps

o Nominal

Current, In : 500 A

o Trip

setting, Im : 9 – 14 x In

o Trip

Rating : 3150 - 6250 Amps

o Trip

setting : > locked rotor current

§

Consideration

Soft starter is equipped with

MCP to against locked rotor and short circuit. Due to operation of soft starter

only for starting motor and after that it will be bypassed when steady state

(normal running) is achieved. Therefore, it need to added other MCP on the

upstream to protect running motor.

The MCP(motor) trip setting is

set 600% FLA by manufacturer and can not/forbidden be change. To prevent

overlap protection, the MCP is set more than 600% FLA.

§

Setting

1. Thermal

O/L

Trip setting : 125% of FLA (according ANSI/NFPA 70 – 2002,

article 430.32(1))

Þ

Trip setting = 1.25 x 378.1 Amps = 472.63 Amps,

so trip setting = 480 Amps.

2. The

motor circuit protection (MCP)

Þ

Im = 9 x In or equal to 4500A

§

Time Current Curves of Protection Coordination.

See attachment #1

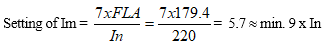

3.2.2 Largest motor at MCC “U”

§

Protective Scheme One Line Diagram

§

Protected Equipment:

The

protection is intended to protect motor against overload, short-circuit and

locked rotor.

·

Tag Number :

1155-PM-702 – Elec. Fire Water Pump

·

Model, Manufacturer : Squirrel cage induction motor / US Motor

·

Rating :

125 HP

·

Full load Current (FLA) : 179.4 Amps

·

Locked Rotor :

6 x FLA

·

Starting device :

Soft starter (manufacturer: Cutler-Hammer)

·

Service factor :

1.15

§

Protective device:

·

MCCB 3P (Thermal-Magnetic Breaker)

o

Manufacturer :

Merlin Gerin

o

Model :

NS250H + MA220

o Type : MCCB 3P

o Frame : 250 Amps

o Nominal

Current, In : 220 A

o Trip

setting, Im : 9 – 14 x In

§

Consideration

See above paragraph.

§

Setting

1. Thermal

O/L

Trip setting : 125% of FLA (according ANSI/NFPA 70 – 2002,

article 430.32(1))

Þ

Trip setting = 1.25 x 179.4 Amps = 224.3 Amps,

so trip setting = 250 Amps.

2. The

motor circuit protection (MCP)

Þ

Im = 9 x In or equal to 1980A

§

Time Current Curves of Protection Coordination,

see attachment #2

3.3 Coordination Relay – Case #1

Overcurrent Protection

Coordination for Largest Motor at MCC

“A” & Main Switchgear

o

o Protective device & others data:

§ Motor

Protection (see paragrap 4.2.1)

§ Protective

device at main switchgear outgoing feeder to MCC “A”:

¨

Feeder Name: 52-F3

¨

Manufacturer/type: Merlin Gerin/ ACB 3P –

NW20H1+Microlgic 6.0A

¨

Rating: 2000AT/2000AF

¨

Nominal Current, In = 2000A

¨

Breaking Capacity (Icu) = 100 kA

§ Equipment

cable:

¨

Size: 3 x 3/C # 2/0 AWG,

¨

Insulation: XLPE

§ Max.

3 phase fault at MCC “A” & Main Switchgear = 52.7 kA rms-sym, see

short-circuit calculation C-1100-ELE-004.

§ Max.

current flows to MCC “A” is 688A, see load flow calculation C-1100-ELE-002.

o Setting

Feeder 52-F3, ACB 4P (NT08H1) + Micrologic

6.0A

Þ

So setting of Ir is 0.7 x In or equal to 1400A

This “Relay” is backup

protection of downstream breaker (motor breakers) and to protect MCC “A” bus

bar. Largest motors is considered due to highest current flow during starting.

Referring to coordination

curve on attachment #1, setting of micrologic 6.0A is determined as

follow:

Þ

Setting of tr = 6s @ 6 x Ir (8400 A)

Þ

Setting of Isd = 5 x Ir (7000 A at 3 s)

Þ

Setting of I2t(OFF at 10 Ir) = 0.2s

(at 14000A)

Þ

Setting of Ii = 15 x In (30000A at 0.05s)

Value

|

|

Ir (x In)

|

0.7

|

ts

(@6Ir)

|

4

|

Isd

(x Ir)

|

5

|

tsd

(i2t)

|

0.2 OFF

|

Ii

(In)

|

15

|

Ig

|

A

|

tg

(i2t)

|

0.1 OFF

|

Þ

In =

2000A

Note: The above

setting is also applied for Feeder 52-F3

(MCC “B”)

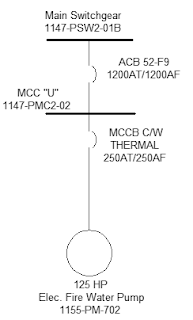

3.4 Coordination Relay – Case #2

Overcurrent Protection

Coordination for Largest Motor at MCC

“U” & Main Switchgear

o

Protective Scheme One Line Diagram

o Protective device & others data:

§ Motor

Protection (see paragraph 4.2.2)

§ Protective

device at main switchgear outgoing feeder to MCC “U”:

¨

Feeder Name: 52-F9

¨

Manufacturer/type: Merlin Gerin/ ACB 3P –

NW12H1+Microlgic 6.0A

¨

Rating: 1250AT/1250AF

¨

Nominal Current, In = 1250A

¨

Breaking Capacity (Icu) = 100 kA

§ Equipment

cable:

¨

Size: 2 x 3/C # 1/0 AWG,

¨

Insulation: XLPE

§ Max.

3 phase fault at MCC “U” & Main Switchgear = 52.7 kA rms-sym, see

short-circuit calculation C-1100-ELE-004.

§ Max.

current flows to MCC “U” is 413A, see load flow calculation C-1100-ELE-002.

o Setting

Feeder 52-F9, ACB 4P (NT08H1) + Micrologic

6.0A

Þ

So setting of Ir is 0.7 x In or equal to 875A

This “Relay” is backup

protection of downstream breaker (motor breakers) and to protect MCC “A” bus

bar. Largest motors is considered due to highest current flow during starting.

Referring to coordination

curve on attachment #2, setting of micrologic 6.0A is determined as

follow:

Þ

Setting of tr = 16s @ 6 x Ir (5250 A)

Þ

Setting of Isd = 4 x Ir (3500 A at 3 s)

Þ

Setting of I2t(OFF at 10 Ir) = 0.1s

(at 8750A)

Þ

Setting of Ii = 10 x In (18750A at 0.05s)

Value

|

|

Ir (x In)

|

0.7

|

ts

(@6Ir)

|

8

|

Isd

(x Ir)

|

4

|

tsd

(i2t)

|

0.2 OFF

|

Ii

(In)

|

15

|

Ig

|

A

|

tg

(i2t)

|

0.1 OFF

|

In

= 1250A

3.5 Coordination Relay – Case #3

Overcurrent

Protection Coordination for MCC “Camp” and Main Switchgear 1147-PSW2-01

o

Protective Scheme One Line Diagram

o Protective device & others data:

§ Largest

outgoing feeder MCC “Camp”

·

Manufacturer :

Merlin Gerin

·

Type/model :

MCCB / NS100H + TM100D (80-100)

·

Rating :

In = 100A

·

Breaking Capacity (Icu) = 70 kA

§ Protective

device at incoming side of MCC “Camp”: ACB 4P (NT08H1) + Micrologic 6.0A.

¨

Manufacturer/type: Merlin Gerin/ ACB 4P –

NT08H1+Microlgic 6.0A

¨

Rating: 800AT/800AF

¨

Nominal Current, In = 800A

¨

Breaking Capacity (Icu) = 65 kA

§ Protective

device at outgoing feeder of Main Switchgear:

¨

Manufacturer/type: Merlin Gerin/ ACB 3P –

NT08H1+Microlgic 6.0A

¨

Rating: 1250AT/1250AF

¨

Nominal Current, In = 1250A

¨

Breaking Capacity (Icu) = 100 kA

§ 3

phase fault, see short-circuit calculation C-1100-ELE-004:

¨

MCC “Camp” = 6.8 kA rms-sym

¨

Main switchgear 1147-PSW2-01A = 52.7 kA rms-sym

§ Maximum

current flows to MCC “Camp” is equal to full load current transformer

1163-PTR2-01 “A or B”

§ Transformer

1163-PTR2-01

¨

Manufacturer/type: Unindo/Oil Immersed

¨

Rating: 400 kVA, 400/400V, D-Y

solid grounded

¨

Thermal capability curve : IEC curve

¨

Inrush Current = 5 x Inominal or

2887A, 1 second (see datasheet DS-1163-PTR2-01)

o Setting

1.

Setting of MCCB (NS100H + TM100D)

Þ

Setting of Ir = 1 x In or equal 100A

Þ

Setting of Ii = 800A (fixed)

2. Camp Incoming Feeder 52-1A, ACB 4P (NT08H1)

+ Micrologic 6.0A

Maximum current flows to MCC

“Camp” :

then,

Þ

So setting of Ir is 0.8 x In (640A)

This “Relay” is backup

protection of downstream breaker and to protect MCC bus bar. The maximum 3

phase fault is same with downstream. Referring to coordination curve on

attachment #3, setting of micrologic 6.0A is determined as follow:

Value

|

|

Ir (x In)

|

0.8

|

ts

(@6Ir)

|

4

|

Isd

(x Ir)

|

2

|

tsd

(i2t)

|

0.2 OFF

|

Ii

(In)

|

10

|

Ig

|

A

|

tg

(i2t)

|

0.1 ON

|

In

= 800A

Note: The above settings are also

applied for Incoming Feeder 52-1B

3. Main Switchgear Outgoing Feeder 52-F5, ACB

4P (NW12H1) + Micrologic 6.0A

This “Relay” is backup

protection of downstream breaker and also protect cable feeder and transformer

if fault occur between both breakers. Referring to coordination curve on

attachment #3, setting of micrologic 6.0A is determined as follow:

\

Setting of Ir

Þ

So setting of Ir is 0.7 x In (875A)

Þ

Setting of tr = 8s @ 6 x Ir (4320A)

Þ

Setting of Isd = 4 x Ir (3500 A at 3)

Þ

Setting of I2t(OFF at 10 Ir) = 0.1s

(at 7200A)

Þ

Setting of Ii = 9 x In (7200 A at 0.05s)

Value

|

|

Ir (x In)

|

0.7

|

ts

(@6Ir)

|

10

|

Isd

(x Ir)

|

4

|

tsd

(i2t)

|

0.4 OFF

|

Ii

(In)

|

15

|

Ig

|

A

|

tg

(i2t)

|

0.1 OFF

|

In

= 1250A

Þ

Note: The above

settings are also applied for Outgoing

Feeder 52-F8

3.6 Coordination Relay – Case #4

Overcurrent

Protection Coordination for PDB-Operation Bldg, Switchgear 1162-PSW2-01, and

Main Switchgear 1147-PSW2-01

o

Protective Scheme One Line Diagram

o Protective device & others data:

§ Largest

outgoing feeder PDB “Operation Building”

·

Manufacturer :

Merlin Gerin

·

Type/model :

MCCB / NS100H + TM100D (80-100)

·

Rating :

In = 100A

·

Breaking Capacity (Icu) = 70 kA

§ Protective

device at incoming of PDB “Operation Building”:

¨

Manufacturer/type: Merlin Gerin/ MCCB 4P –

NS400N+STR23SE

¨

Rating: 400AT/400AF

¨

Nominal Current, In = 400A

¨

Breaking Capacity (Icu) = 45 kA

§ Protective

device at outgoing feeder of switchgear 1162-PSW2-01A:

¨

Manufacturer/type: Merlin Gerin/ ACB 4P –

NT06H1+Microlgic 6.0A

¨

Rating: 400AT/400AF

¨

Nominal Current, In = 400A

¨

Breaking Capacity (Icu) = 42 kA

§ Protective

device at outgoing feeder of Main Switchgear:

¨

Manufacturer/type: Merlin Gerin/ ACB 3P –

NW12H1+Microlgic 6.0A

¨

Rating: 1250AT/1250AF

¨

Nominal Current, In = 1250A

¨

Breaking Capacity (Icu) = 100 kA

§ 3

Phase Fault, see short-circuit calculation C-1100-ELE-004:

¨

PDB “Op. Bldg.” = 6.3 kA rms-sym

¨

Switchgear 1162-PSW2-01 = 6.7 kA rms-sym

¨

Main switchgear 1147-PSW2-01A = 52.7 kA rms-sym

§ Maximum

current flows to MCC “Camp” is equal to full load current transformer

1162-PTR2-01 “A or B”

§ Transformer

1162-PTR2-01

¨

Manufacturer/type: Unindo/Oil Immersed

¨

Rating: 250 kVA, 400/400V, D-Y

solid grounded

¨

Thermal capability curve : IEC curve

¨

Inrush Current = 5 x Inominal or

1805A, 1 second (see datasheet DS-1162-PTR2-01)

o Setting

1.

Setting of MCCB (NS100H + TM100D)

Þ

Setting Ir = 1 x In or equal 100A

Þ

Setting Ii = 800A (fixed)

2.

Setting of MCCB (NS400N+STR23SE)

From load flow study

C-1100-ELE-002, operating current flows to 1162-PDB2-01A is 81 ampere

Ir = 2*81 = 162A

Þ

Setting of long time delay,

§

Io = 0.9 x

In or equal 360A

§

Ir = 0.8 x Io or equal to 288A

Þ

Setting of short time delay, Im = 5 x Ir or equal 1440A

Þ

Setting of instantaneous, Ii = 11 x In (fixed)

or equal to 4400A

3. Op. Building Incoming Feeder 52-1A, ACB 4P

(NT06H1) + Micrologic 6.0A

Maximum current flows to

switchgear “Op. Bldg” :

Þ

So setting of Ir is 0.95 x In or equal to 380A

This “Relay” is backup

protection of downstream breaker and also to protect switchgear bus bar.

Referring to coordination curve on attachment #4, setting of micrologic 6.0A is

determined as follow:

Value

|

|

Ir (x In)

|

0.6

|

ts

(@6Ir)

|

8

|

Isd

(x Ir)

|

6

|

tsd

(i2t)

|

0.2 OFF

|

Ii

(In)

|

10

|

Ig

|

A

|

tg

(i2t)

|

0.2 OFF

|

In = 630A

Note: The above settings are

also applied for Incoming Feeder 52-1B

4. Main Switchgear Outgoing Feeder 52-F2, ACB

3P (NW12H1) + Micrologic 6.0A

This “Relay” is backup

protection of downstream breaker and also protect cable feeder and transformer

if fault occur between both breakers. Referring to coordination curve on

attachment #4, setting of micrologic 6.0A is determined as follow:

Value

|

|

Ir (x In)

|

0.6

|

ts

(@6Ir)

|

12

|

Isd

(x Ir)

|

5

|

tsd

(i2t)

|

0.4 OFF

|

Ii

(In)

|

15

|

Ig

|

A

|

tg

(i2t)

|

0.1 OFF

|

In = 1000A

Note: The above settings are

also applied for Outgoing Feeder 52-7

3.7 Coordination Relay – Case #5

Overcurrent

Protection Coordination for Largest Outgoing (Main Switchgear) and GTG’s

Breaker (Normal Operation)

o

Protective Scheme One Line Diagram

o Protective device, others data and

setting:

§ In

normal operation, largest outgoing feeder of Main Switchgear is to MCC “A/B”.

Setting of the ACB, refer to paragraph 4.3 (Normal Condition – GTG’s ON)

§ Protective

device at incoming of Main Switchgear: Multilin SR 489 – Over current with

Voltage Restraint, see paragraph 5.1.6

§ 3

Phase Fault, see short-circuit calculation C-1100-ELE-004:

¨

Main switchgear 1147-PSW2-01A = 52.7 kA rms-sym

¨

Max. fault current is supplied by GTG = 18.9 kA

o Consideration/formula

Relay time dial setting.

Refer to ANSI extremely Inverse Curve for characteristic of the inverse

time relay. Since GTG’s breaker is as backup relay, it must be coordinated with

outgoing breaker(micrologic) of main switchgear. By adding a coordination time

interval (CTI) 0.3s to them, the setting of Multilin O/C relay is more than

0.5s for Max. Fault Current supplied by GTG.

then from ANSI curve; it is

found TMD = 4 & operating time of

relay is about 1.2s at 18.9kA.

o Setting:

See paragraph 4.1.6.1, section

phase O/C (A)

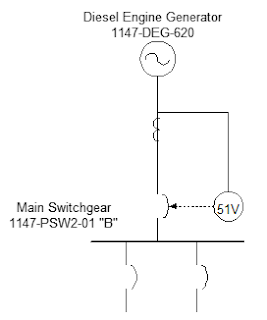

3.8 Coordination Relay – Case #6

Overcurrent

Protection Coordination for Largest Outgoing (Main Switchgear) and DEg’s

Breaker (Emergency Operation)

o

o Protective device, others data and

setting:

§ In

emergency operation, Largest outgoing feeder of Main Switchgear is to MCC “U”.

Setting of this ACB, refer to paragraph 4.4 (Normal Condition – GTG’s ON)

§ Protective

device at incoming of Main Switchgear: Multilin SR 489 – Over current with

Voltage Restraint, see paragraph 5.1.6

§ Max.

Fault, see short-circuit calculation C-1100-ELE-004:

¨

Main switchgear 1147-PSW2-01”B” = 52.7 kA

rms-sym

¨

Max. fault Current is supplied by DEG = 10.8 kA

o Consideration/formula

Relay time dial setting.

Refer to ANSI extremely Inverse Curve for characteristic of the inverse

time relay. Since DEG’s breaker is as backup relay, it must be coordinated with

outgoing breaker(micrologic) of main switchgear. By adding a coordination time

interval (CTI) 0.3s to them, the setting of Multilin O/C relay is more than

0.5s for Max. Fault Current supplied by DEG.

then from ANSI curve; it is

found TMD = 10 & operating time of

relay is about 3s at 10.8kA.

o Setting:

See paragraph 4.1.6.1, section Phase

O/C (B).

3.9 Ground Fault

Relay

o Protective device & others data:

A. at MCC “Camp”

¨

Manufacturer/type: Merlin Gerin/ ACB 4P –

NT08H1+Microlgic 6.0A

¨

Rating: 800AT/800AF

¨

Nominal Current, In = 800A

B. at Switchgear “Op. Bldg”

¨

Manufacturer/type: Merlin Gerin/ ACB 4P –

NT06H1+Microlgic 6.0A

¨

Rating: 400AT/400AF

¨

Nominal Current, In = 400A

o Consideration

The purpose of this relay is not

to limit fault damage of equipment but to protect human life, so that it need

high sensitivity to detect ground fault.

o Setting

A. Ground Fault Relay

(Micrologic 6.0A) at MCC “Camp”

Þ

Ground Fault Pickup, Ig = In x A (minimum setting A= 0.2, see attachment #3)

Þ

Time delay (ms) at In, I2t Off = 0.2

B. Ground Fault Relay

(Micrologic 6.0A) at Switchgear ”Op. Bldg”

Þ Ground

Fault Pickup, Ig = In x A (minimum

setting A= 0.3, see attachment #3)

Þ Time

delay (ms) at In, I2t Off = 0.2

0 Response to "How to setting Relay Coordination"

Post a Comment